For commercial buildings, from apartment complexes and hotels to townhome communities and mixed-use developments, the exterior envelope is more than a facade. It’s a high-performance system engineered to protect the structure from the elements, control energy use, and provide year-round comfort for tenants and guests.

Commercial envelope design demands a layered, systems-based approach that integrates structural support, moisture control, energy efficiency, and aesthetic appeal. When planned and executed well, these solutions reduce operational costs, extend building lifespan, and help maintain compliance with local codes and environmental certifications.

What Is the Commercial Building Envelope?

The building envelope is everything that separates the interior of a structure from the outside world:

- Wall systems

- Roofing systems

- Foundation systems

- Openings such as windows and doors

- Cladding, insulation, air/vapor barriers, and weatherproofing layers

In larger commercial buildings, this may also include curtain walls, rainscreens, or insulated metal panels.

Choosing the Right Cladding & Siding for Commercial Exteriors

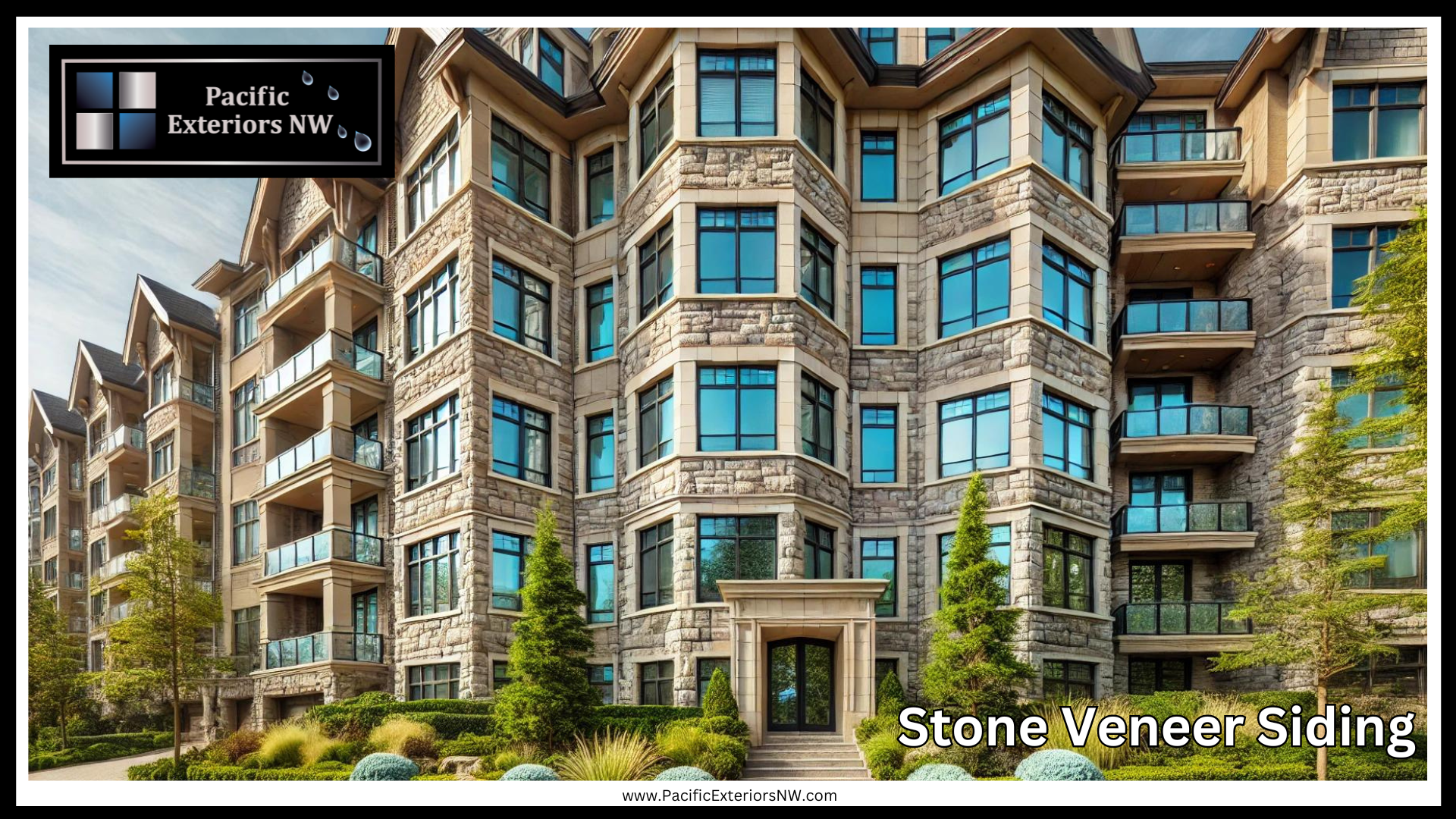

The visible layer of the envelope, cladding, or siding performs both functional and aesthetic roles. It must resist rain, UV exposure, and temperature extremes while complementing the building’s design.

Common Commercial Cladding Options:

- Metal Panels (Steel/Aluminum): Durable, fire-resistant, and low-maintenance. Common in modern and industrial-style buildings.

- Fiber Cement Panels: Resilient to moisture, insects, and fire. Suitable for multi-family housing.

- EIFS (Exterior Insulation and Finish Systems): Lightweight, energy-efficient, and ideal for smooth finishes.

- Brick & Stone Veneer: Offers a timeless appearance and high durability, often used on lower levels or for accent walls.

- Composite Panels: Blend materials for performance and ease of installation.

- Rainscreen Systems: Include an air gap to promote drainage and drying, critical for wet or coastal climates.

Insulation Systems: Maximizing Energy Efficiency

In commercial construction, insulation must meet or exceed code requirements for thermal resistance while integrating seamlessly with other envelope components.

Options include:

- Continuous Insulation (CI): Applied across all structural members to eliminate thermal bridging

- Spray Foam: Expands into gaps, ideal for complex assemblies

- Rigid Foam Boards: High R-values per inch, often used in curtain walls

- Mineral Wool: Provides both thermal and fire resistance

High-performance envelopes prioritize R-value optimization and thermal continuity to minimize heating and cooling loads throughout the seasons.

Air and Moisture Barriers: Hidden Layers That Matter

Managing moisture and air infiltration is essential in protecting the structure and interior air quality.

- House Wraps or Weather-Resistive Barriers (WRBs): Applied over sheathing to stop bulk water

- Peel-and-Stick or Liquid Membranes: Create seamless, continuous moisture protection

- Vapor Barriers: Installed where needed to prevent condensation based on climate zone

- Drainage Planes: Direct water away from the wall assembly

- Air Sealing: Stops drafts and improves HVAC efficiency

Together, these elements form a breathable but watertight envelope.

Structural Backbone: Framing and Sheathing

Behind the layers of protection are the components that give the building its form and load-bearing capacity.

- Steel or Wood Framing: Provides vertical and lateral support

- Structural Sheathing (Plywood, OSB, Gypsum): Adds rigidity and forms the substrate for WRBs

- Foundation Systems: Require moisture control, such as waterproof membranes and drain tiles

In wet environments like the Pacific Northwest, crawl space encapsulation and basement waterproofing are essential to reduce ground moisture migration.

Roof Assembly: First Line of Defense From Above

Roof integration is a major element in envelope design:

- Roof Membranes: TPO, EPDM, or PVC for flat or low-slope roofs

- Flashing and Edge Detailing: Prevent water intrusion around transitions

- Gutters and Scuppers: Direct water off the roof and away from walls

- Attic or Plenum Ventilation: Reduces moisture buildup and supports energy efficiency

- Ice Dam Prevention: Important for buildings in colder climates

Windows and Doors: Vulnerable Points That Require Precision

Window and door integration is a known weak point in envelope systems if not done properly. Commercial projects must prioritize:

- Flashing Integration: Around window and door openings to guide water away

- Sealant Application: High-performance silicone or polyurethane sealants

- Rough Opening Prep and Shimming: Ensures an airtight installation

- Thermal Break Frames & Low-E Glass: Improve efficiency and reduce condensation

Codes, Standards, and Testing

Meeting local codes and performance standards is critical in commercial construction:

- IECC Compliance: Energy codes for envelope performance

- ASHRAE Standards: Thermal comfort and energy efficiency

- NFRC Window Ratings: Measure U-factor, SHGC, and VLT

- ASTM/AAMA Testing: Validates water resistance and structural performance

- Blower Door Testing & Thermal Imaging: Used for performance verification

- LEED, WELL, and Passive House Certifications: For sustainable projects

Integrated Design Approaches

Modern construction embraces a whole-building systems approach where all elements—structure, HVAC, windows, insulation—are coordinated from the design phase.

- Passive House & Net-Zero Energy Design: For ultra-low-energy buildings

- Design-Build Collaboration: Ensures materials and systems work together seamlessly

- Deep Energy Retrofits: Upgrade envelope systems in older buildings to modern standards

Climate-Specific Envelope Strategies

Commercial envelope design must align with the building’s local environment:

- Moisture Management: For coastal, humid, or rainy regions

- UV Resistance: For sunny or high-altitude environments

- Freeze-Thaw Durability: In climates with temperature swings

- Wind Load & Impact Ratings: For storm-prone areas

- Seismic Design Considerations: In earthquake-prone zones

Getting It Done Right: Installation and Quality Control

Professional installation is the final piece of the puzzle:

- Sequenced Installation: Follows a correct order to prevent failures

- Field Testing & Inspections: Catch issues before occupancy

- Joint Sealing, Fastening Systems, and Connection Detailing: Ensure longevity and performance

Who Supports This Work?

- Envelope Consultants & Building Scientists: Design, troubleshoot, and test assemblies

- Energy Auditors: Identify performance gaps and savings opportunities

- Weatherization Contractors: Improve envelope performance in existing buildings

- Performance Testing Specialists: Verify air and moisture control effectiveness

Commercial Exterior Envelope Solutions: Investing in Longevity

Upgrading or designing a commercial building with modern exterior envelope solutions isn’t just about aesthetics—it’s about risk management, operational efficiency, and long-term ROI. From moisture resistance to code compliance and tenant comfort, each layer and detail contributes to a more resilient and efficient structure.

By selecting the right materials, ensuring proper installation, and tailoring your approach to the local climate, your building can withstand the elements while reducing energy consumption and maintenance costs for years to come.

Frequently Asked Questions (FAQs)

What is a commercial building envelope, and why does it matter?

It’s the system of walls, roof, windows, doors, insulation, and barriers that separates the interior from external conditions. It influences energy use, comfort, moisture control, and building durability.

What cladding performs best in rainy or humid climates?

Metal panels, fiber cement, rainscreens, and composite panels with drainage capabilities are top choices for wet environments.

How do you prevent mold and water damage in commercial buildings?

By integrating air/vapor barriers, drainage planes, proper flashing, and breathable insulation, plus annual inspections and maintenance.

Do envelope upgrades help with tenant retention?

Yes. Improved comfort, lower utility bills, and fewer maintenance issues create a better tenant experience, reducing turnover.

Can envelope improvements reduce HVAC loads?

Absolutely. Well-insulated, airtight envelopes reduce heating and cooling demand, thereby lowering operating costs and extending the lifespan of HVAC systems.